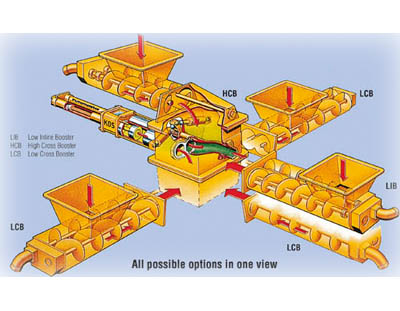

Feeding Equipment Double Augers

For thick media, which cannot be ingested automatically, feeding equipments with self-cleaning augers are installed on the suction side. The conveyed material in the feed hopper is kneaded intensively by augers, mixed up and pressed into the cylinders to achieve a high volumetric efficiency factor.

Description

Features and advantages

- Combing augers clean up self-acting from adhesive materials.

- Strong hydraulic drive for optimal adjustment of the turning moment to the conveyed material.

- Different configurations of the feeding equipment to the high-density solids pump for optimal room utilization in the facility.

- Available in construction steel or high-quality steel according to the consistency of the conveyed material.

Description

For thick media, which cannot be ingested automatically, feeding equipments with self-cleaning augers are installed on the suction side. The conveyed material in the feed hopper is kneaded intensively by augers, mixed up and pressed into the cylinders to achieve a high volumetric efficiency factor.

By this method also semisolid, earth-moist and visually dry looking materials can be conveyed into the cylinders.

The design of the augers define the intensity of the mixture. By the turbulent stream in the pump and the feed line it is intensified.

A mixopress equipment can add several additional components continuously.